Advanced ProductPrototyping

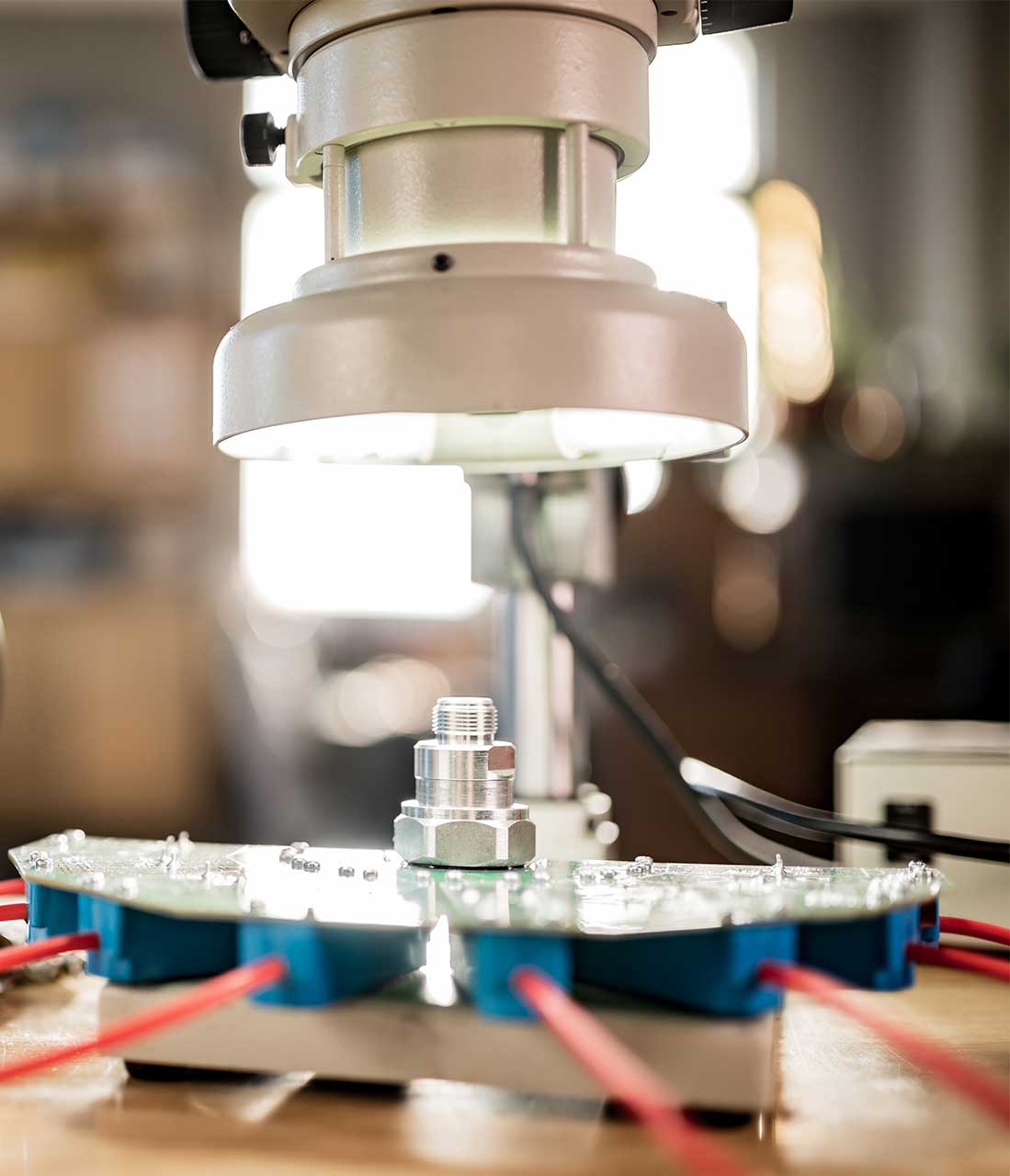

At Nova Plastics, our prototyping services are designed to bring your ideas to life with precision and efficiency. We use advanced techniques to create detailed prototypes, allowing for thorough testing and refinement before moving to full-scale production. This iterative process ensures that your final product meets all design specifications and performance criteria.

Our Services

Prototyping

Our prototyping services enable clients to visualize and test their designs before full-scale production. This process helps in identifying potential issues and making necessary adjustments, ensuring the final product meets all specifications.

Concept Validation

Our Concept Validation service is designed to help clients refine and confirm their initial design concepts before committing to full-scale production. By developing functional prototypes, we enable you to test and evaluate key aspects of your design, including functionality, usability, and overall user experience. This early-stage testing is crucial for identifying potential issues and making necessary adjustments. With our support, you can ensure that your concept is practical and meets all required specifications, reducing risks and improving the final product's success.

Design Optimization

We offer design optimization by analyzing and refining prototypes to ensure that all design aspects align with requirements and standards. This stage includes testing materials and manufacturing methods to achieve the best possible performance.

Pre-Production Testing

Our pre-production testing allows clients to identify and address potential issues before starting serial production. This step involves thorough testing and evaluation of prototypes to ensure reliability and durability of the final product.

Our prototyping services help perfect your designs before full-scale production. Contact us to discuss how we can bring your vision to life.

Our Approach

How We Deliver Results

-

Detailed Analysis

We start with a detailed analysis of your project requirements to understand your goals and needs. This foundation allows us to craft a tailored approach that aligns with your vision and objectives.

-

Iterative Refinement

Our iterative refinement process involves continuous testing and feedback to enhance prototypes. This method ensures ongoing improvements and adjustments, leading to a final product that meets your expectations.

-

Rigorous Quality Control

We implement rigorous quality control measures throughout the prototyping phase. This ensures that each prototype is thoroughly tested and refined to meet the highest standards of quality and reliability.

Our Materials

Material Options and Specifications

We offer a diverse selection of materials to meet various application requirements. Here are some of the materials we work with:

Fluid Transfer Tubing

Ideal for various fluid transfer applications, offering flexibility and durability.

ABS Sheets and Rods

Known for their strength and rigidity, ABS materials are perfect for a range of applications.

HDPE

High-Density Polyethylene is known for its high strength-to-density ratio, making it suitable for many applications.

UHMW

Ultra-High Molecular Weight Polyethylene is highly durable and resistant to wear and impact.

Nylon

This versatile material offers excellent mechanical properties, including high strength and wear resistance.

Polycarbonate

Known for its high impact resistance and optical clarity, polycarbonate is used in many demanding applications.